Smart manufacturing employing big data analytics (BDA) and the Internet of Things (IoT) has helped Intel to address its current and future manufacturing needs while producing a clear return on its investment. Intel’s pilot program utilized building blocks from hardware and software suppliers to create a scalable solution for differentiating manufacturing operations with business intelligence. The pilot is forecasted to save Intel millions of dollars annually, along with other business value that Intel is still realising. The monitoring, analytics and modelling provided by the company’s smart manufacturing solution allowed Intel to improve equipment component uptime, minimise yield losses, facilitate predictive maintenance and reduce component failures.

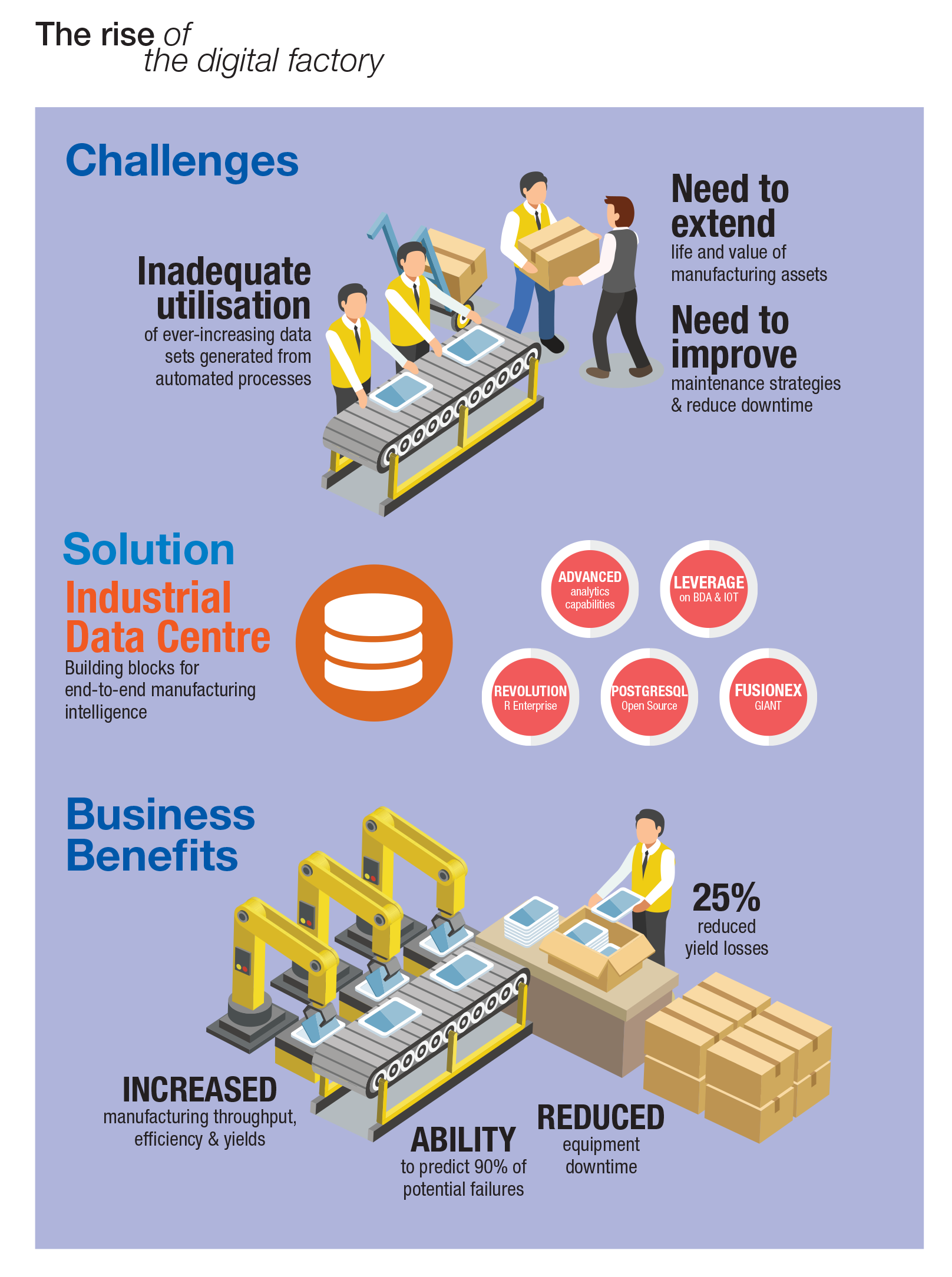

Challenges:

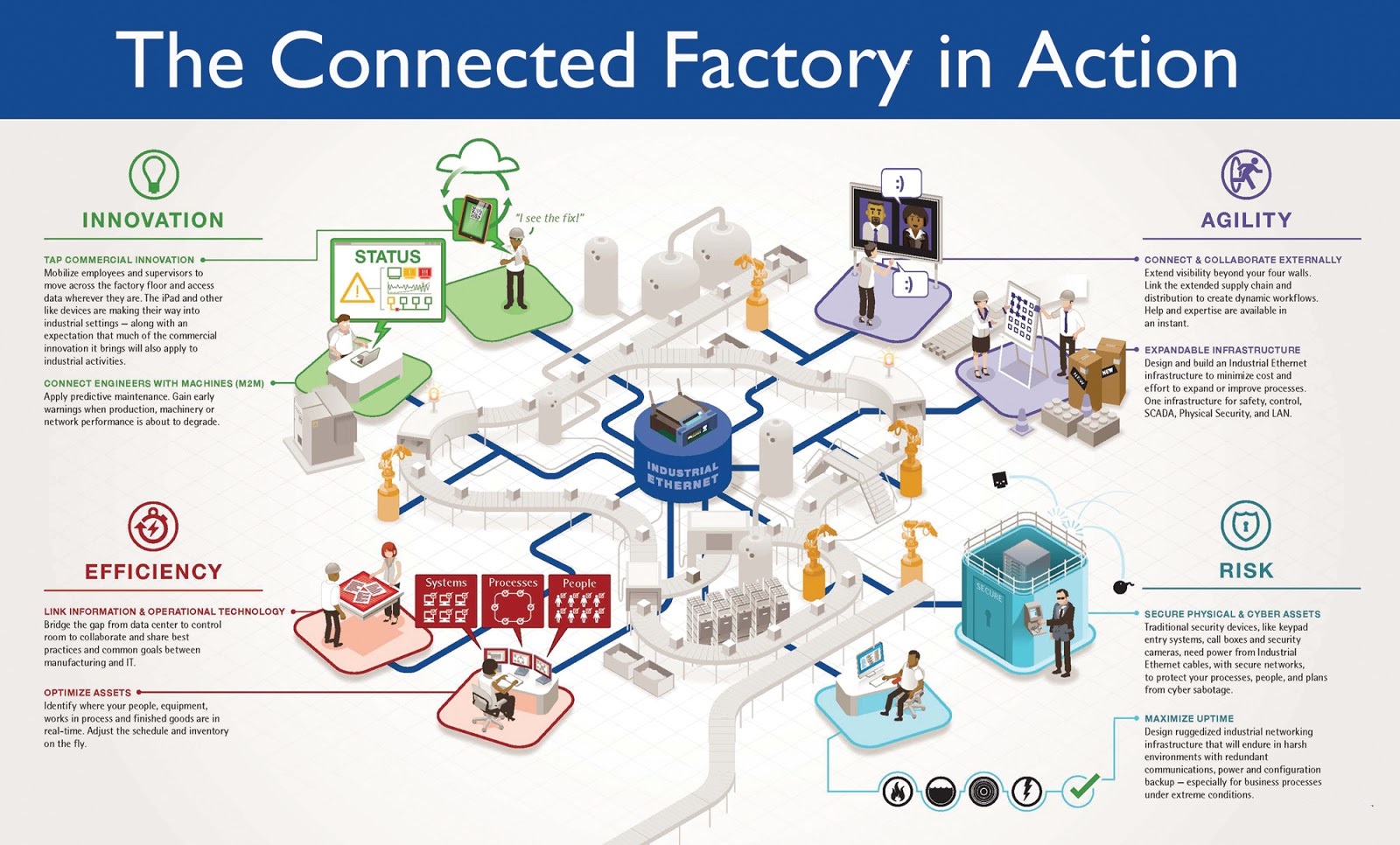

We realised that its automated processes were generating an ever-increasing volume of data that was not being adequately utilised. Data from disparate sources, including on the network and shop floor, could potentially be leveraged through IoT to enhance decision-making, leading to better manufacturing efficiency and increased product yields and quality.

Intel also required a BDA solution that could store, analyse and extract useful information from the massive data sets generated in manufacturing, which comprised of different types of structured, semi-structured and unstructured data. The implementation needed to deliver insights that would help Intel extend the life and value of its manufacturing assets by using data to improve maintenance strategies and prevent costly downtime.

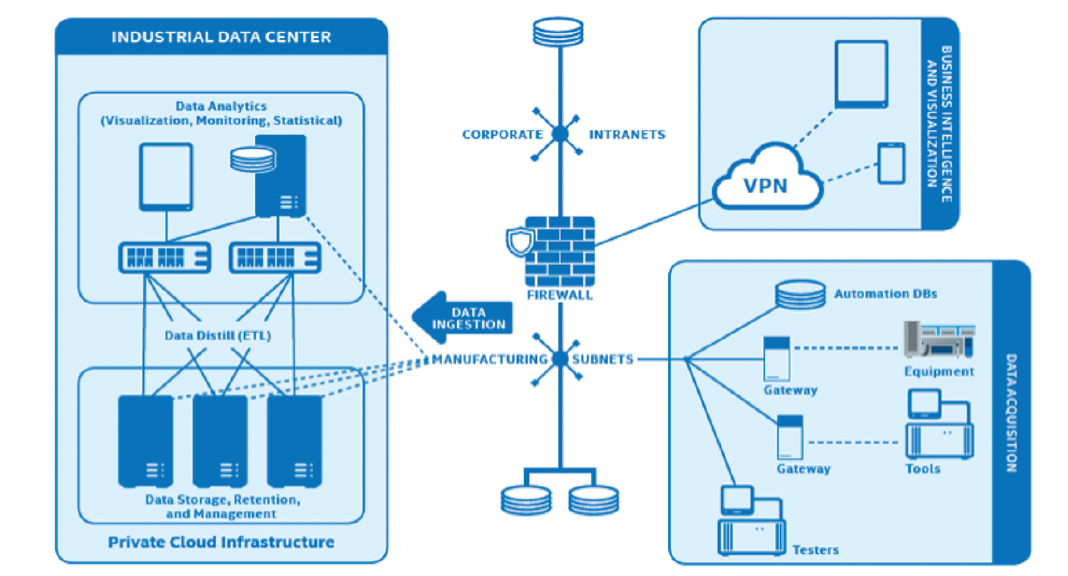

Intel looked for an overall solutions matrix made up of end-to-end building block suppliers to enable manufacturing intelligence from the factory floor to the Industrial Data Center (IDC). Key considerations included scalable infrastructure and capabilities to provide clear return on investment (ROI) on the solution and the ability to statistically use manufacturing data from disparate sources to differentiate existing operations.

Technical Solution:

The end-to-end manufacturing intelligence solution from factory floor to the IDC also included software and hardware building blocks from Cloudera, Dell, Mitsubishi Electric and Revolution Analytics.

Building blocks for end-to-end manufacturing to enable intelligence.

The IDC caters to the needs of local factory operations and resides in the local manufacturing shop floor control room. Each IDC ran on a Dell PowerEdge VRTX hardware platform hosting the data analytics and application software, as well as Cloudera Hadoop nodes running in multiple virtual machines (VMs). The analytics and application software workloads included Revolution R Enterprise from Revolution Analytics, the PostgreSQL open source object-relational database, and Fusionex GIANT.

The Intel BDA pilot programme also implemented IoT gateway devices to transmit manufacturing data from factory equipment to the IDC.

Business Benefits

The solution ultimately provided four main benefits which are increased manufacturing throughput; higher yields; improved efficiency; and reduced downtime. Intel also recorded results and benefits in three very distinct problem areas across different types of data and production processes.

Intel reduced its non-genuine production yield loss through monitoring and analysis of machine parametric values and timely replacement of parts before they fail. By using monitoring and analytics, Intel was able to predict up to 90 percent of potential failures of test equipment and the early notification prompted the replacement of defective test equipment before incorrect diagnoses could occur. This reduced yield losses from false diagnoses of manufactured devices as being faulty by 25 percent.

Intel also reduced its yield losses by minimising incorrect ball assembly in ball attach equipment. By visualising and correlating sensor readings with various machine and execution data, Intel was able to minimise incorrect ball assembly in solder ball attach equipment. This resulted in reduced yield losses, optimised maintenance costs and avoidance of sudden equipment downtime.

By using image classification to identify good or defective units – Intel’s use of image analytics identified defective units from a pool of marginal units ten times faster than manual inspections, saving the time required to ensure product quality.

The Future:

This pilot project is forecasted to save Intel millions of dollars annually with additional ROI business values. Some of the benefits include improving equipment component uptime, minimizing wrong classification of good units as bad thereby increasing yield and productivity, enabling predictive maintenance, and reducing component failures. There are many other types of parametric, metrology, product, and equipment data which could be mined and analyzed to extract new business values. This project provides the opportunity to increase factory efficiency and productivity – all of which boosts Intel’s competitive advantage.

* from MIMOS