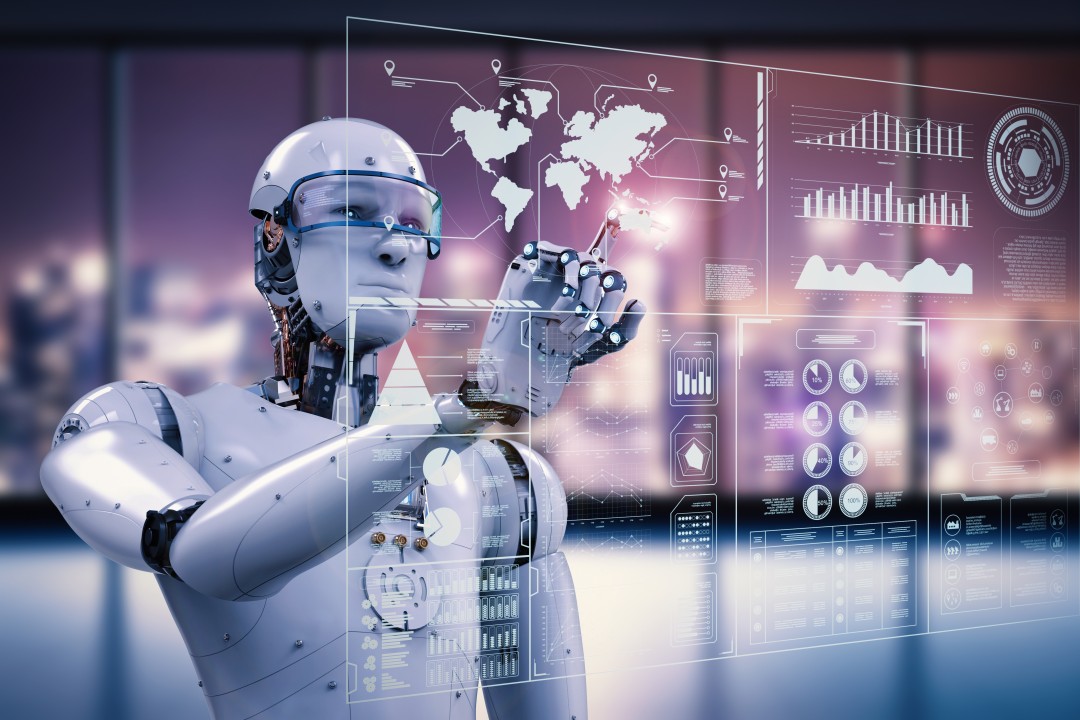

Start your imaginations

Glimpse into an Industry 4.0 Digital Transformation Journey

Key factors in digital factory transformation

Connectivity

processes, machines, and people are connected to improve efficiency.

Optimization

high levels of automation to increase uptime and productivity.

Agility

configurable factory layouts and implementation of product changes in real-time.

Transparency

visibility across all operations to allow real-time decision making.

Proactive

automated re-stocking, fault detection, and safety monitoring.